Ceramic Boat Evaporation in High Vacuum

Efficient Thin-Film Deposition for Functional Packaging Films

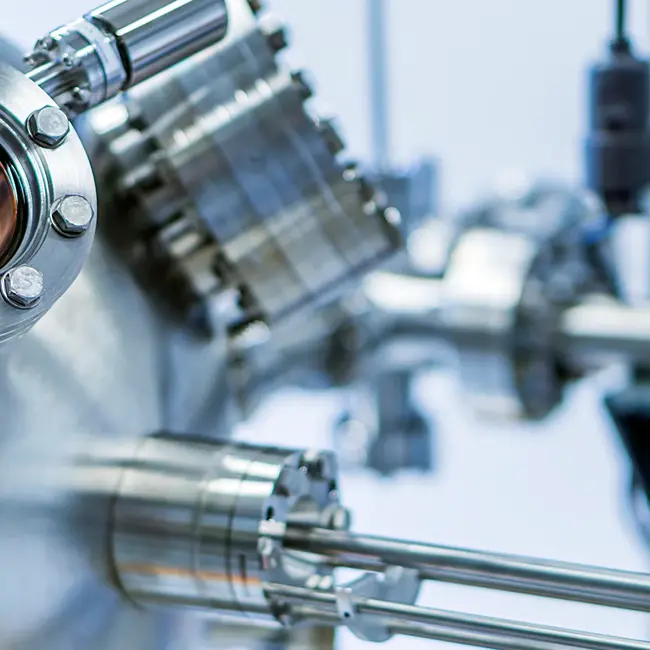

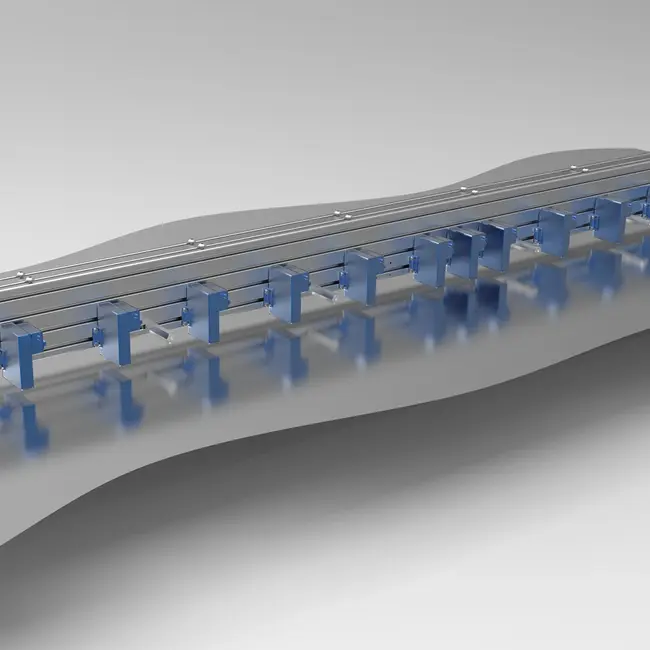

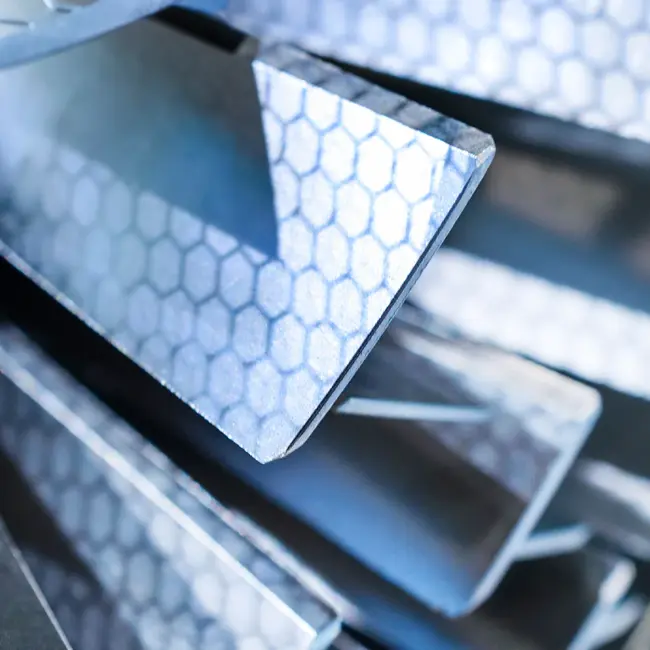

In the packaging industry, ceramic boat evaporation is an established thermal PVD process used primarily for depositing thin metal layers (e.g., aluminum) onto polymer substrates such as PET, BOPP, or CPP. The evaporation material is placed in a ceramic boat, which is resistively heated to temperatures above its evaporation point. The resulting metal vapor condenses on the continuously transported web, forming a uniform and functional coating.

This technology enables high deposition rates while maintaining excellent film quality and process stability—key factors for applications requiring barrier properties, optical reflectivity, or decorative effects.

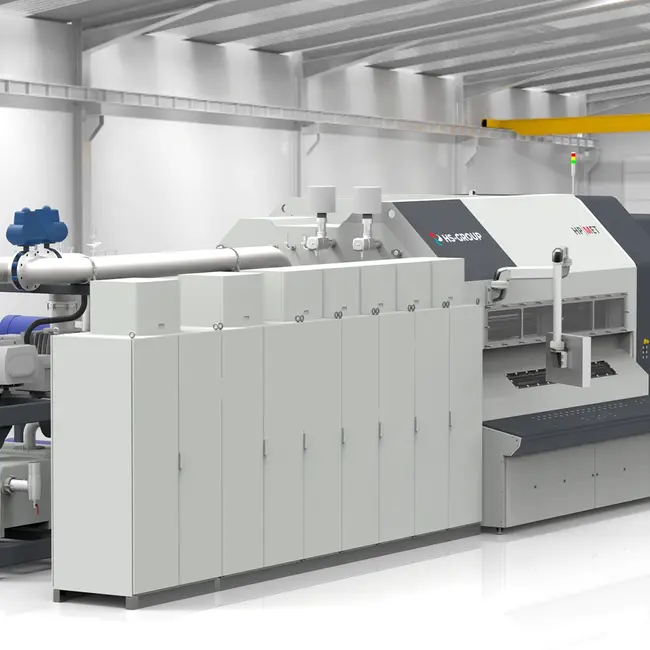

Ceramic boats offer significant advantages: they are chemically inert, low in particle generation, and thermally robust, ensuring a clean and stable process environment. In modern roll-to-roll vacuum coating systems, ceramic boat evaporation remains a core technology for the economical and reproducible production of high-performance packaging materials.